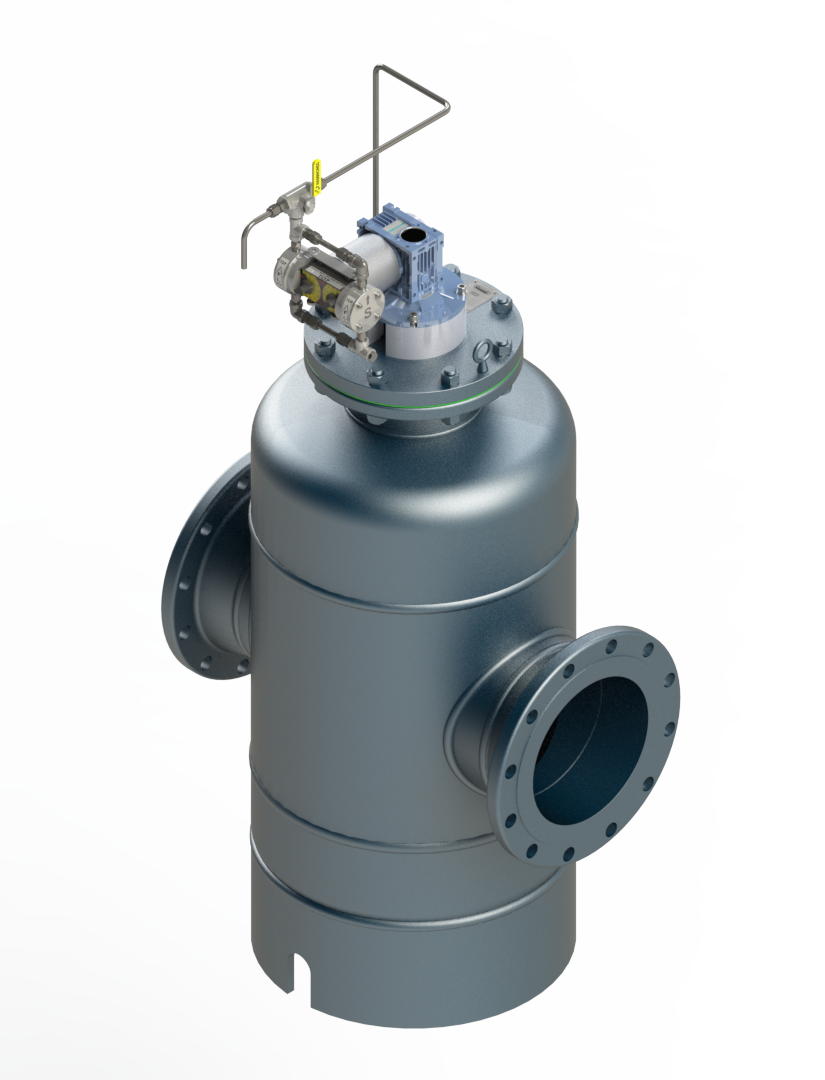

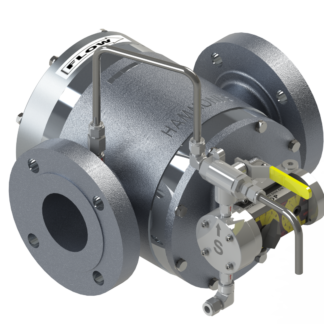

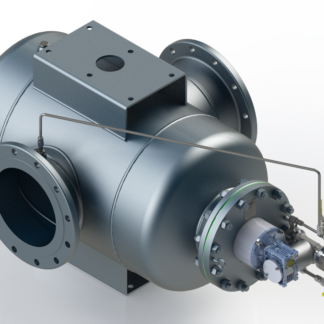

Description

The 10T Series system offers single or multiple additive injection at flow rates typically found in fuel delivery terminals and transport trailer fill stands. The unique turbine-powered fluid motor is designed to inject precisely for applications that operate with a constant flow rate. Like all Hammonds injection systems, the 10T dispenses precise quantities of additive at a continuous rate, eliminating the “slugging” effect typically found in meter-pulsed injectors. The additive in injected just ahead of the driver, providing complete, consistent additive blending.