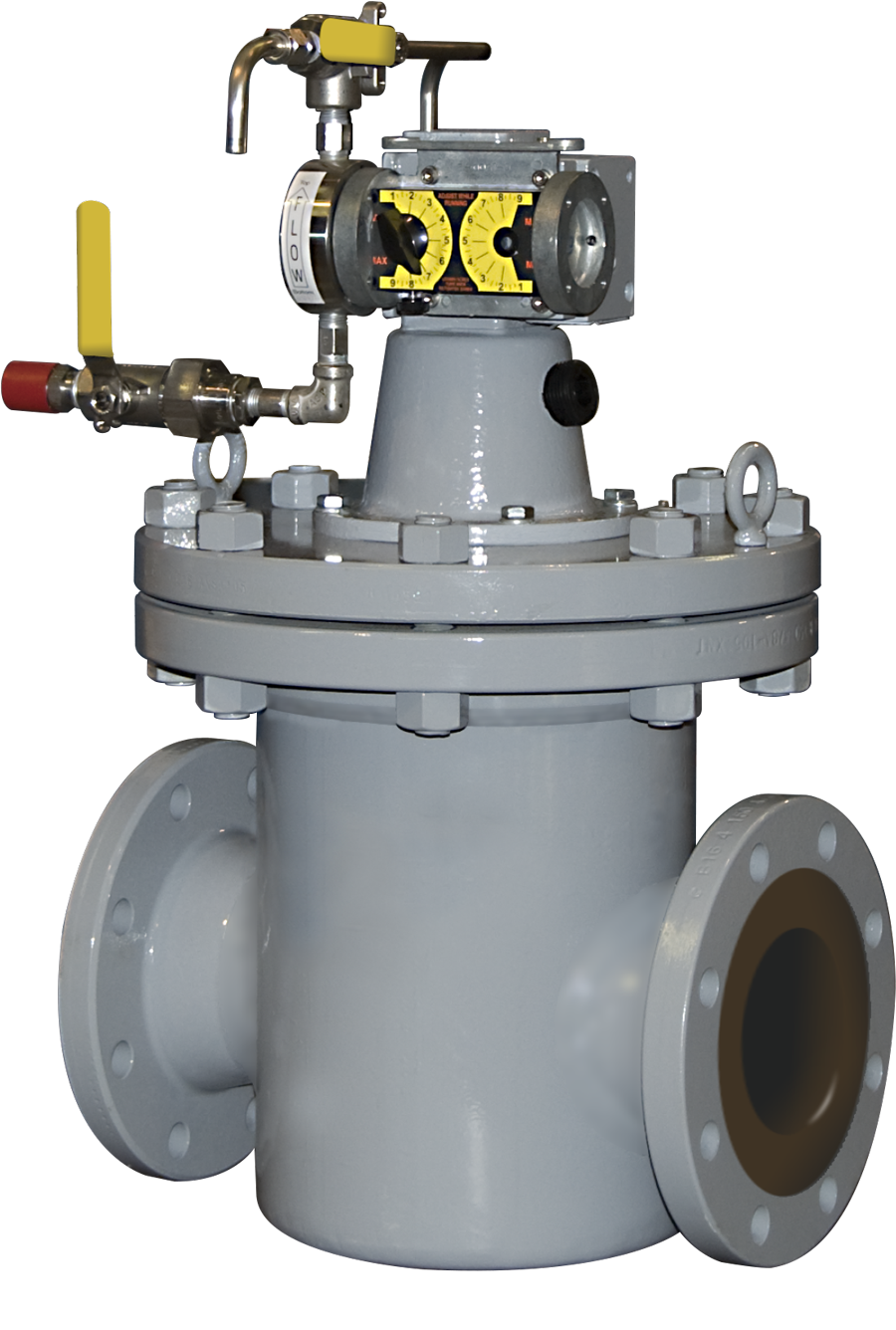

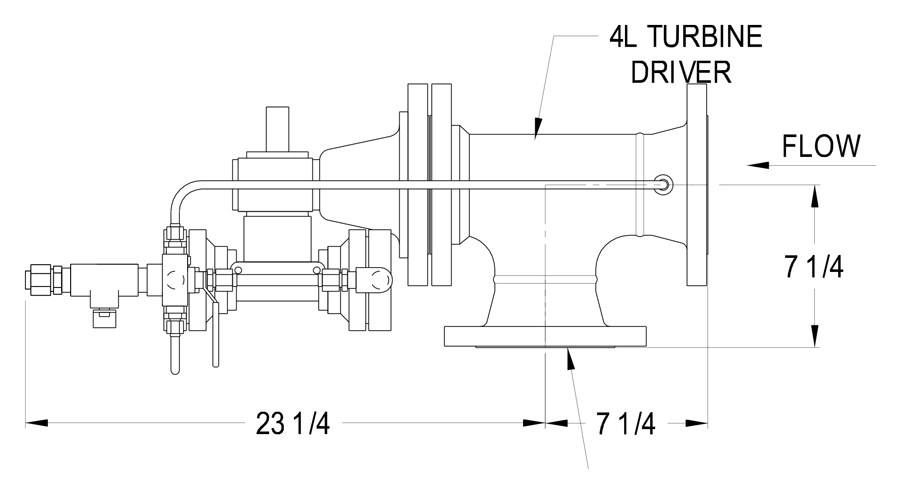

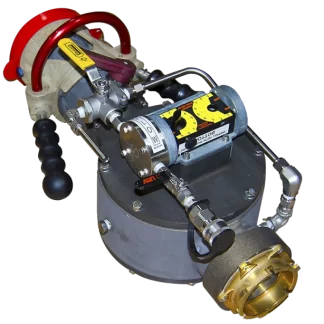

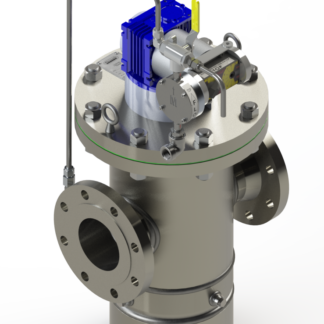

Description

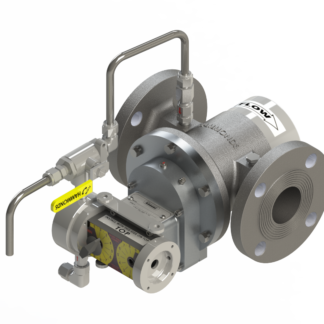

The 4L Series system offers single or multiple additive injection at flow rates typically found in fuel delivery terminals and transport trailer fill stands. The unique turbine-powered fluid motor responds precisely to changes in product volume even at lower product flow rates. Like all Hammonds injection systems, the 4T dispenses precise quantities of additive at a continuous rate, eliminating the “slugging” effect typically found in meter-pulsed injectors.