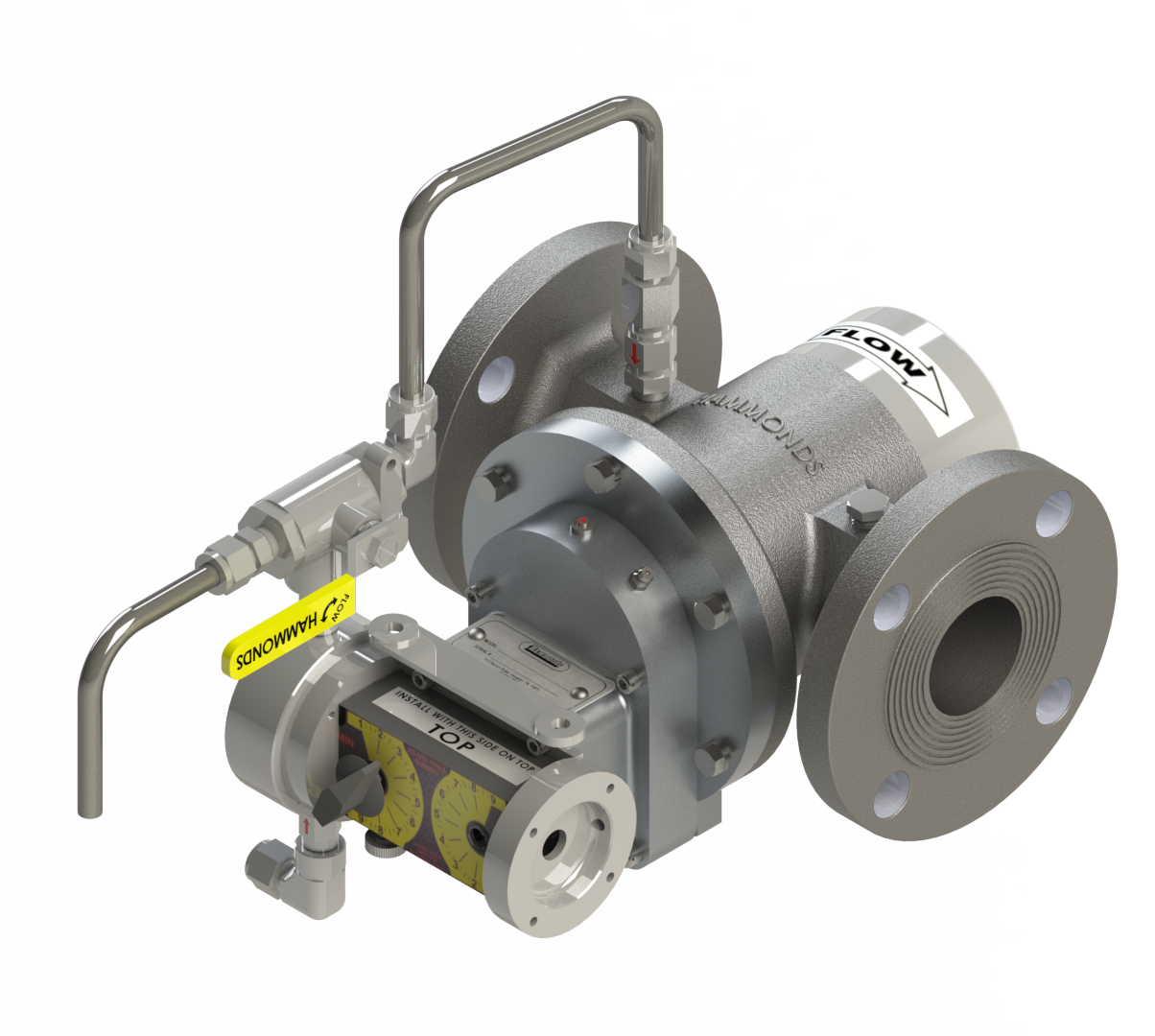

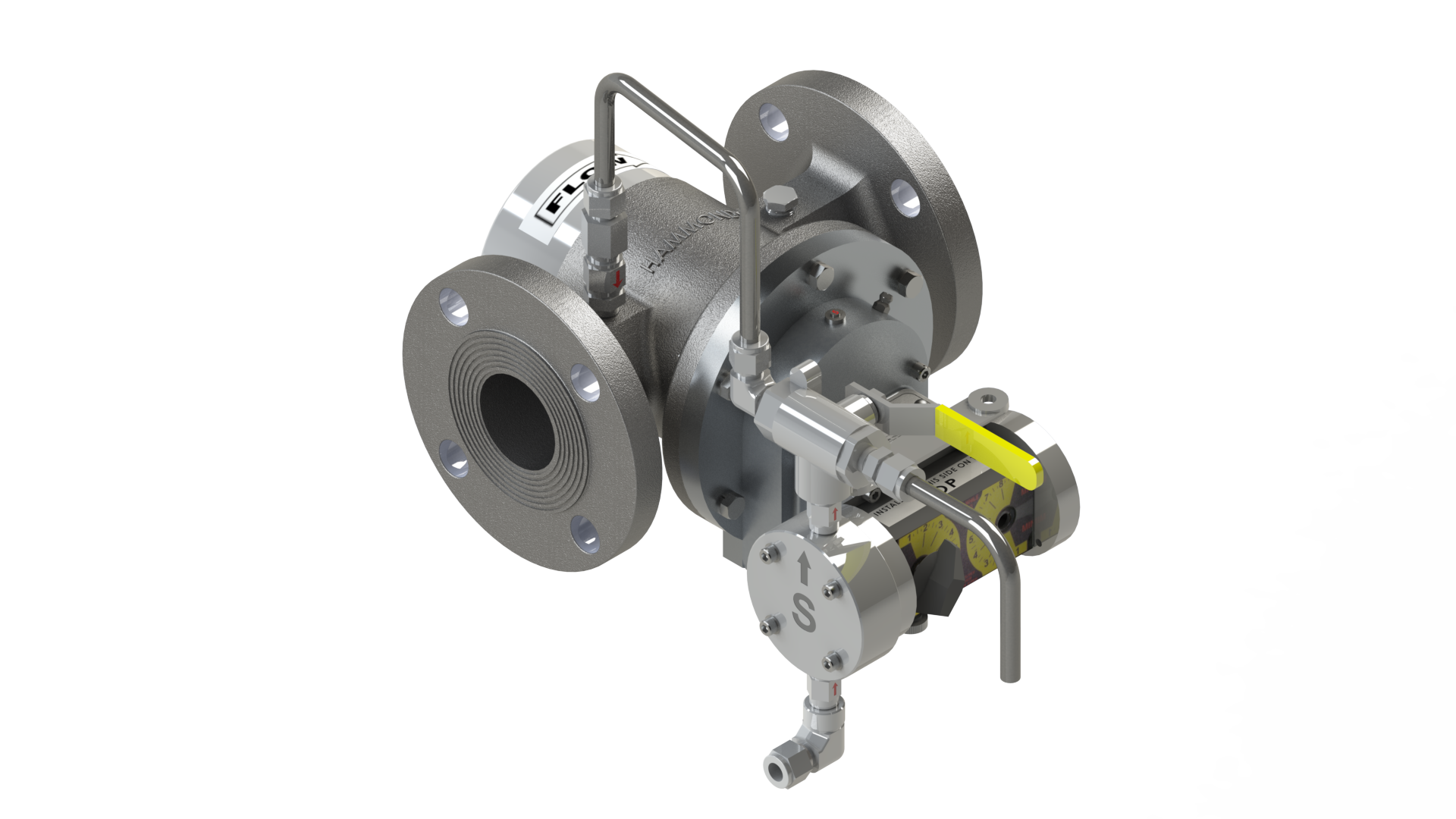

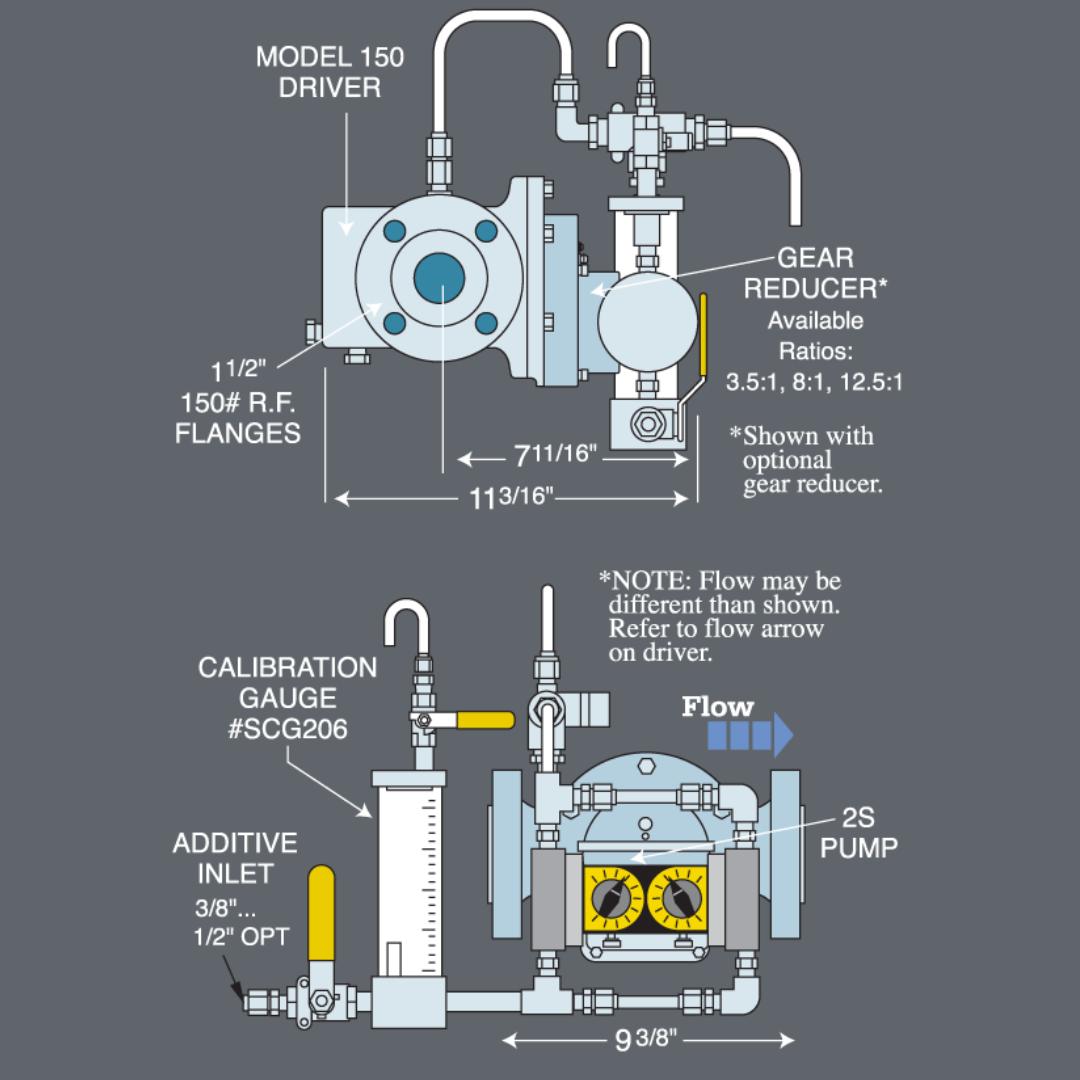

Description

The Model 150 offers the ability to inject single or dual additives at lower flow rates (7-75 gallons per minute). The 150 is capable of responding accurately to changes in low-flow rates and providing an even and accurate additive ratio despite those fuel flow rate changes.

Ideal applications include self-fueling cabinets, home heating oil delivery trucks, dye injection and low-flow aviation fuel delivery trucks.

The Model 150 is a scaled -down version of Hammonds popular Model 600 and can be easily adapted for water treatment. The 150 is also an economical way ot providing customers with enhanced, value-added fuel.