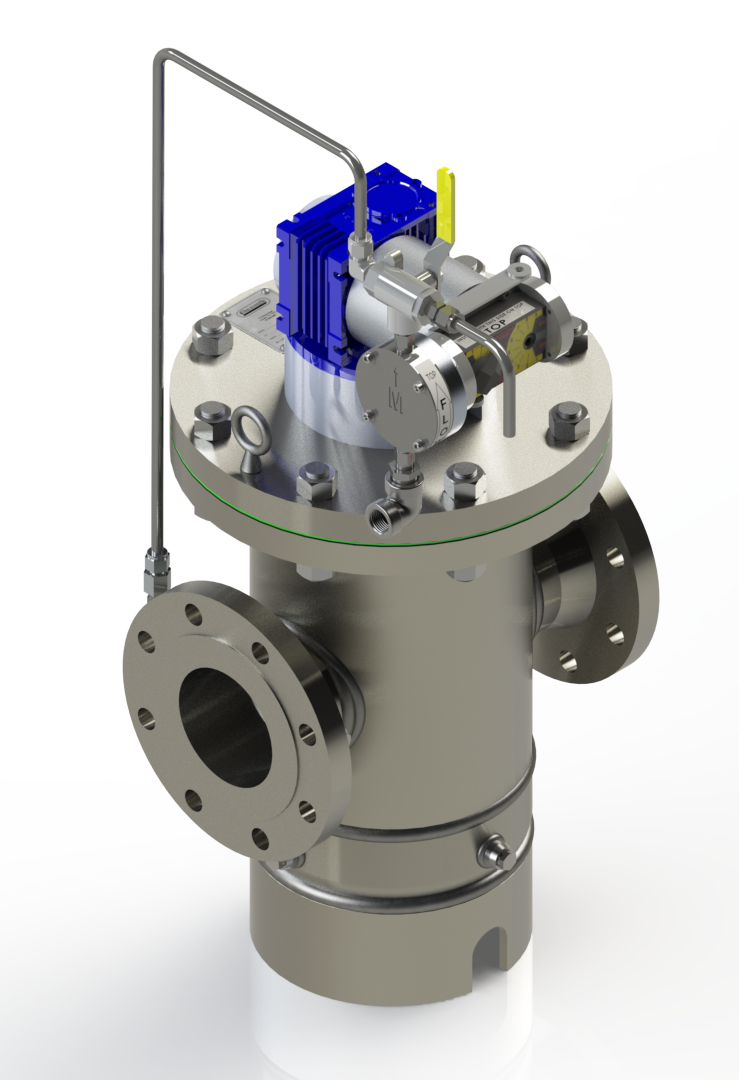

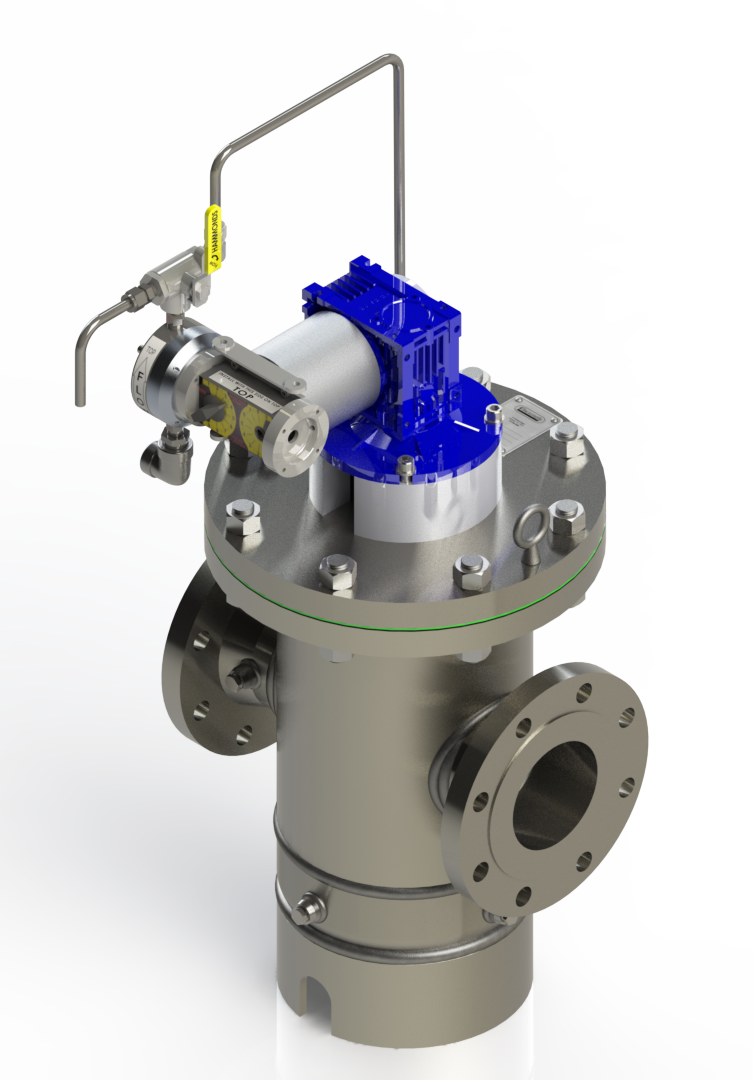

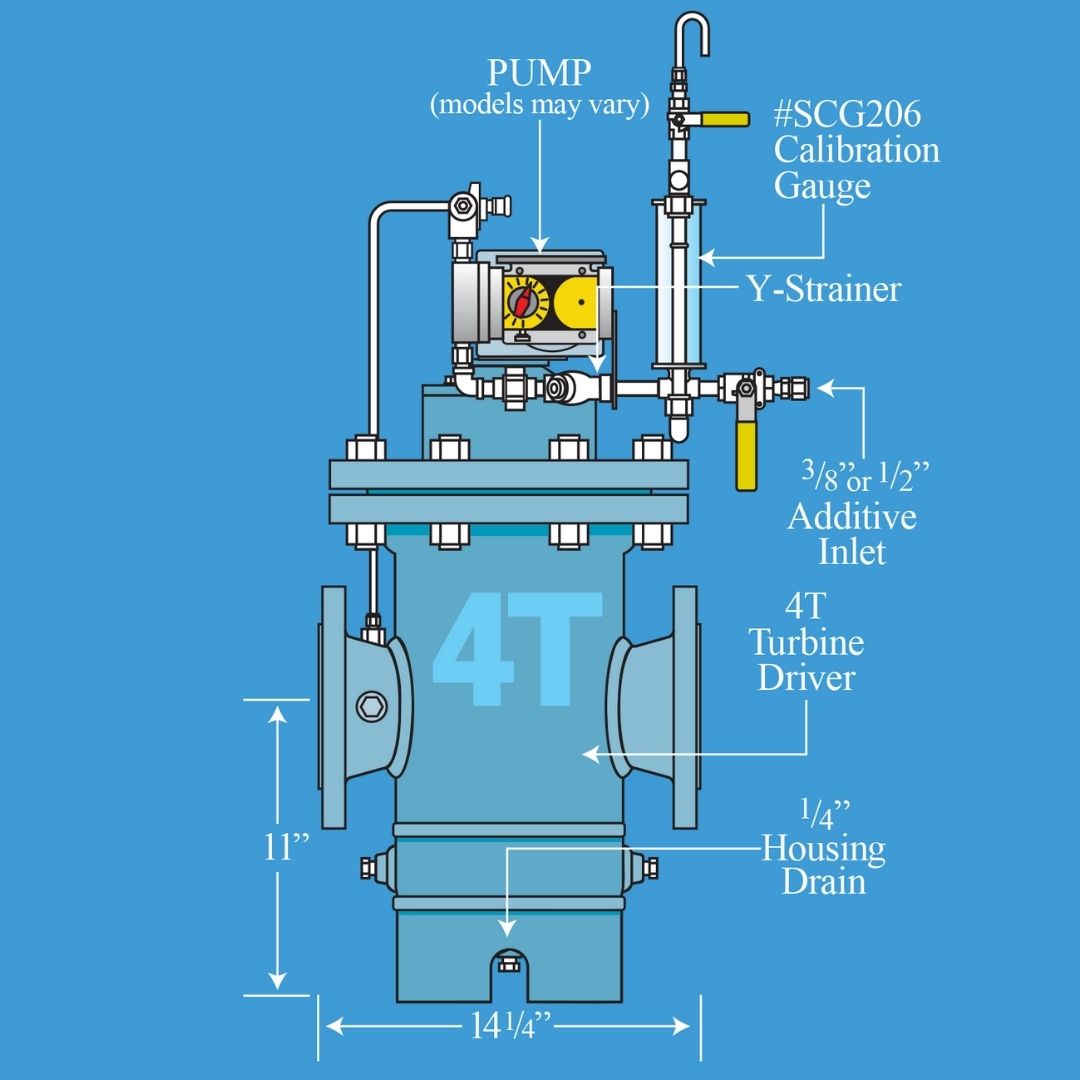

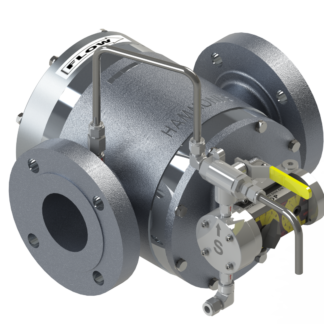

Description

The 4T Series system offers single or multiple additive injection at flow rates typically found in fuel delivery terminals and transport trailer fill stands. The unique turbine-powered fluid motor is designed to inject precisely for applications that operate with a constant flow rate. Like all Hammonds injection systems, the 4T dispenses precise quantities of additive at a continuous rate, eliminating the “slugging” effect typically found in meter-pulsed injectors. The additive in injected just ahead of the driver, providing complete, consistent additive blending. As with all Hammonds Fluid-Power Injectors and Injection Systems, the flow of the fuel is the only power source that is necessary. No outside source is required. Because the injector is powered by the flow of fuel, a constant and accurate additive to fuel ratio is maintained. Faster fuel flow results in more additive being injected, and conversely, slower flow results in less additive being injected. This ensures that the correct injection to fuel rate remains in place throughout the process. In addition, the flow of fuel provides a blending of fuel to additive that is always even, accurate and thorough. Additive is never injected by “slugs” or “pulses” like some systems.